COMPUTRENDS Blog

Collaboration, Anytime & Anywhere

3DEXPERIENCE SOLIDWORKS customers achieve up to 10X ROI on each license because of...

Computrends' SOLIDWORKS Training Courses

Computrends is the authorized SOLIDWORKS training center in the Philippines with over 2,000 people trained. Our team of Certified SOLIDWORKS Instructors(CSWI) and Certified SOLIDWORKS Professionals(CSWP) are ready to teach you the essentials as well as the advanced courses of SOLIDWORKS to make you more productive in your work. SOLIDWORKS FEA Simulation courses are also available.

All trainees will received a Certificate of Achievement upon completion of training. Official SOLIDWORKS training manual is also given to serve as your guide after the training.

To know about the schedule of the trainings, click here. For more information about the trainings or to request for a training, please contact us at 632 8111548 / 50 / 76.

SOLIDWORKS BASIC AND ADVANCED COURSES:

- SOLIDWORKS Essentials Training -

Length: 4 days , 9am to 5pm

Prerequisites: Mechanical design experience; experience with the Windows® operating system.

Description: This training teaches you how to use the SOLIDWORKS mechanical design automation software to build parametric models of parts and assemblies, and how to make drawings of those parts and assemblies.

Course outline : read here

- SOLIDWORKS Drawings Training -

Length: 2 days , 9am to 5pm

Prerequisites: Must have taken the SOLIDWORKS Essentials Training Course.

Description: This training teaches you how to make drawings of SOLIDWORKS parts and assemblies.

Course outline : read here

- SOLIDWORKS Assembly Modeling Training -

Length: 2 days , 9am to 5pm

Prerequisites: Must have taken the SOLIDWORKS Essentials Training Course.

Description: This training teaches you how to maximize your use of the assembly modeling capabilities of SOLIDWORKS mechanical design automation software.

Course outline : read here

- SOLIDWORKS Advanced Part Modeling Training -

Length: 3 days , 9am to 5pm

Prerequisites: Must have taken the SOLIDWORKS Essentials Training Course.

Description: This training teaches you how to use multibody solids, sweeping and lofting features, and the more advanced shaping capabilites of SOLIDWORKS.

Course outline : read here

- SOLIDWORKS Surface Modeling Training -

Length: 2 days , 9am to 5pm

Prerequisites: Must have taken the SOLIDWORKS Essentials Training Course and the SOLIDWORKS Advanced Part Modeling Training Course.

Description: This training teaches you how to build freeform shapes using SOLIDWORKS mechanical design automation software.

Course outline : read here

- SOLIDWORKS Mold Design Training -

Length: 2 days , 9am to 5pm

Prerequisites: Must have taken the SOLIDWORKS Essentials Training Course and the SOLIDWORKS Advanced Part Modeling Training Course.

Description: This training teaches you several manual mold creation techniques and how to use the Mold Tools in SOLIDWORKS mechanical design automation software.

Course outline : read here

- SOLIDWORKS Sheet Metal Training -

Length: 2 days , 9am to 5pm

Prerequisites: Must have taken the SOLIDWORKS Essentials Training Course.

Description: This training teaches you how to build sheet metal parts using SOLIDWORKS mechanical design automation software. Building standalone sheet metal parts, and converting conventional parts to sheet metal, including in assembly context, are covered.

Course outline : read here

- SOLIDWORKS Weldments Training -

Length: 1 day , 9am to 5pm

Prerequisites: Must have taken the SOLIDWORKS Essentials Training Course.

Description: This training teaches you how to create welded structures with standard structural members. Weld beads are also covered.

Course outline : read here

- SOLIDWORKS Routing - Electrical Training -

Length: 2 days , 9am to 5pm

Prerequisites: Must have taken the SOLIDWORKS Essentials Training Course.

Description: This training teaches you how to create, edit and manage Electrical routes, from the critical routing components and their design requirements to the sub-assemblies that contain the routes.

Course outline : read here

- SOLIDWORKS Routing - Piping and Tubing Training -

Length: 2 days , 9am to 5pm

Prerequisites: Must have taken the SOLIDWORKS Essentials Training Course.

Description: This training teaches you how to create, edit and manage Piping and Tubing routes, from the critical routing components and their design requirements to the subassemblies that contain the routes.

Course outline : read here

SOLIDWORKS SIMULATION COURSES:

- SOLIDWORKS Simulation Training(Static) -

Length: 2 days , 9am to 5pm

Prerequisites: Must have taken the SOLIDWORKS Essentials Training Course or has knowledge of SOLIDWORKS. Knowledge of basic mechanical engineering concepts is recommended.

Description: This course is designed to make SOLIDWORKS users productive more quickly with the SOLIDWORKS Simulation Bundle. This course will provide an in-depth coverage on the basics of Finite Element Analysis (FEA), covering the entire analysis process from meshing to evaluation of results for parts and assemblies. The class discusses linear stress analysis, gap/contact analysis, and best practices.

Course outline : read here

- SOLIDWORKS Simulation Professional Training -

Length: 1 day , 9am to 5pm

Prerequisites: Must have taken the SOLIDWORKS Simulation(Static) Training Course or must have working knowledge of the SOLIDWORKS Simulation software. Knowledge of SOLIDWORKS and basic mechanical engineering concepts is recommended.

Description: This 1 day course will provide an in-depth coverage on the advanced topics in Finite Element Analysis (FEA) including heat transfer analysis, frequency analysis, fatigue, stability analyisis based on the linear buckling concepts, 2D simulations (plane stress, strain and axisymmetry) and pressure vessel modulus. Example or parts and assemblies including those with various gap/contact conditions are reviewed.

Course outline : read here

- SOLIDWORKS Simulation Premium Training -

Length: 4 days , 9am to 5pm

Prerequisites: Must have taken the SOLIDWORKS Simulation(Static) and SOLIDWORKS Simulation Professional Training Courses. The knowledge of basic principles in Vibrations is strongly recommended, but not required

Description: This 4-day class, created for SOLIDWORKS Simulation Premium users, will raise FEA skills to the next level! The first part of the course will teach you the basic and advanced topics in non-linear stress analysis. You will learn how to deal with models that exhibit large displacements and/or yielding, discuss and practice the use of many material models available in SOLIDWORKS Simuation Premium and, most importantly, how to drive a non-linear analysis to successful completion. The second part of the course will expose you to various advanced topics in Dynamics. The material covered includes the time dependent analysis, harmonic analysis and random vibrations.

Course outline : read here

- SOLIDWORKS Flow Simulation Training -

Length: 2 days , 9am to 5pm

Prerequisites: Must have taken the SOLIDWORKS Essentials Course or has knowledge of SOLIDWORKS. Knowledge of basic mechanical engineering concepts is recommended.

Description: This two-day training program provides an in depth session on the basics of fluid flow analysis, in addition to covering meshing concerns, modeling concerns, analysis, post-processing, available options and preferences.

Course outline : read here

- SOLIDWORKS Plastics Training -

Length: 2 days , 9am to 5pm

Prerequisites: Must have taken the SOLIDWORKS Essentials Course or has knowledge of SOLIDWORKS. Must have a fundamental knowledge of plastic materials, plastic part design, and/or injection mold design.

Description: The SOLIDWORKS Plastics course teaches you how to use specialized simulation software tools to predict how melted plastic flows during the injection molding process. Predicting how the plastic will flow enables you to predict manufacturing defects such as weld lines, air traps, short shots, and sink marks. By predicting these defects, you can change the part or mold geometry, the processing conditions, or the plastic material itself to eliminate or minimize them, saving energy, material, time, and money. The SOLIDWORKS Plastics course covers all the features and functions of both SOLIDWORKS Plastics Professional (for part designers) and SOLIDWORKS Plastics Premium (for mold designers).

Course outline : read here

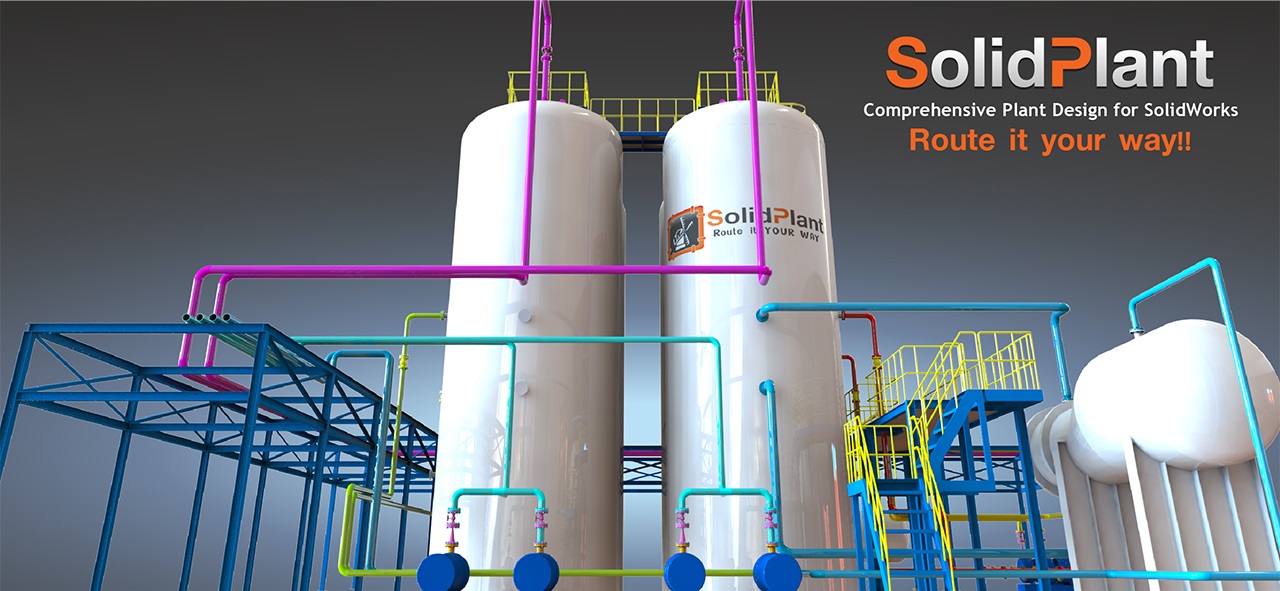

SOLIDPLANT 3D

SolidPlant is the most comprehensive plant design system for SOLIDWORKS. SolidPlant takes advantage of the superior SOLIDWORKS capabilities, and a specification driven plant design system, combining them seamlessly. A great new solution for small- and medium-sized projects with a very competitive pricing. SolidPlant P&ID with SolidPlant 3D makes creating and designing your projects easy and efficient, offering many benefits to EPC's and Owner-Operators. With simple reporting, editing, sharing, validation, and exchange of design information, SolidPlant P&ID and SolidPlant 3D applications helps your projects start easier, run better, and finish smarter. It improves your workflow and saves time.

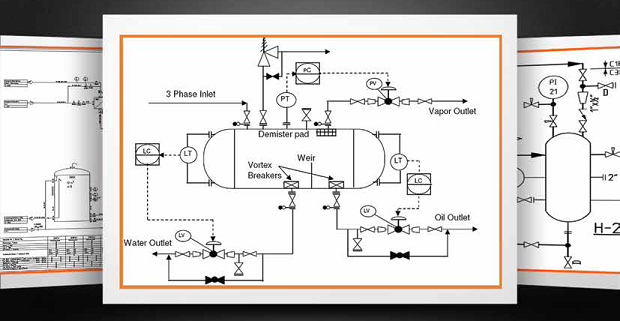

SolidPlant P&ID

Create, modify, and manage piping and instrumentation diagrams with SolidPlant P&ID.

Built on the latest 2D platform, SolidPlant P&ID interface is easy to use and familiar to designers and engineers, so your design team can start immediately with minimal training. Everyday tasks are streamlined and automated to boost productivity, while component and line information is easily accessed as you work.

Download brochure

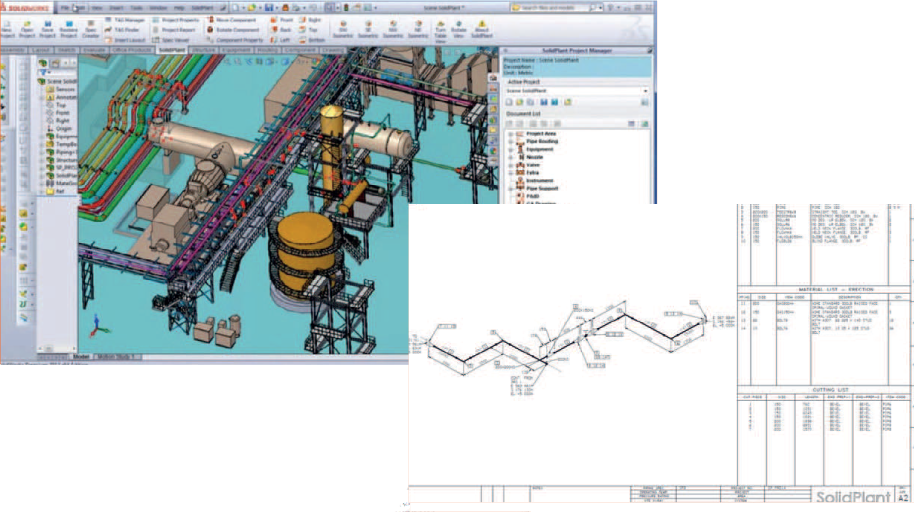

SolidPlant 3D

SolidPlant 3D is a solution which enables the piping designers to design faster, more effectively and accurately in a SOLIDWORKS environment. SolidPlant 3D is an easy-to-use package with a short learning curve.

SolidPlant 3D now brings a real 3D design environment with advanced features to the engineer's desktop. It is able to export an accurate PCF file format that allows you to connect ro other applications. It has also embedded the de facto standard Isometric drawing publisher ISOGEN®. SolidPlant 3D is a 100% database and specifiction driven system, and runs as an add-in to SOLIDWORKS Standard, Professional, and Premium.

Download brochure

3D PRINTERS

MakerBot

IDEAS IN THE MAKING™

Elevate and streamline your desktop 3D printing experience with our full set of connected solutions and services, like accessible, reliable 3D printers, advanced design-to-print software, an expanding collection of apps, free designs from the largest 3D design community in the world, and much more.

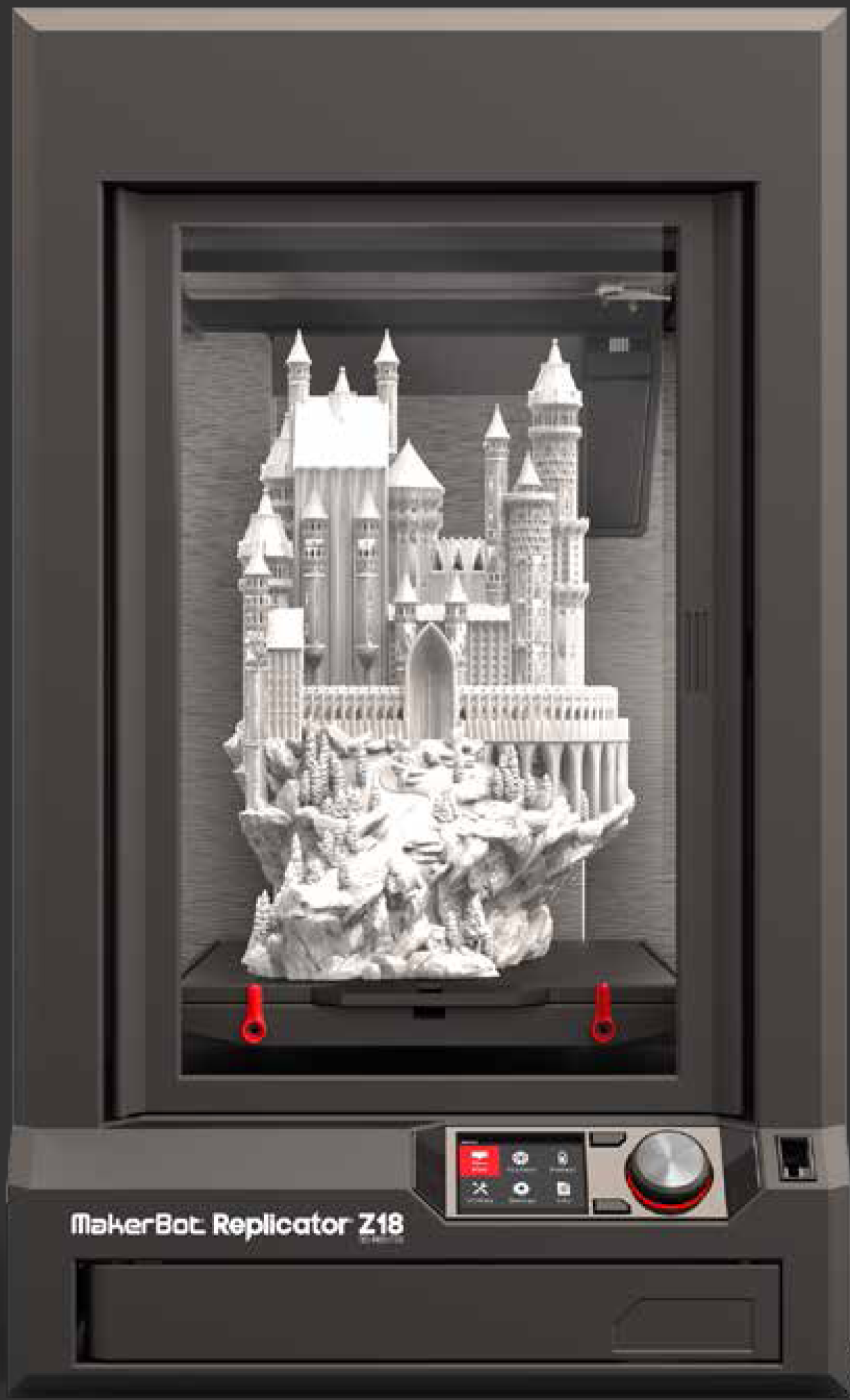

MAKERBOT® REPLICATOR® Z18 3D PRINTER

MASSIVE BUILD VOLUME

- Make extra-large and ultra-tall industrial prototypes, models, and products

- Print multiple things at once so you can get to work on your next design sooner

BEST PRICE/PERFORMANCE IN THE PROFESSIONAL 3D PRINTER CATEGORY

- Enclosed and heated build chamber designed for printing large models with minimal curling

- Fifth generation technology defines the new standard for ease of use, quality, and reliability

- Powered by the new, user-friendly MakerBot Replicator 3D Printing Platform

- New MakerBot Replicator Smart Extruder is easy to swap or replace

PRINT PAPER-THIN LAYERS

- 100-micron layer resolution

- Get smooth-to-the-touch surfaces that don't need sanding, finishing, or postproduction

- Create professional-quality, high-resolution prototypes and complex models

- Create realistic prototypes and models for demonstrations and presentations

- Choose settings that range from fast draft to finer resolution

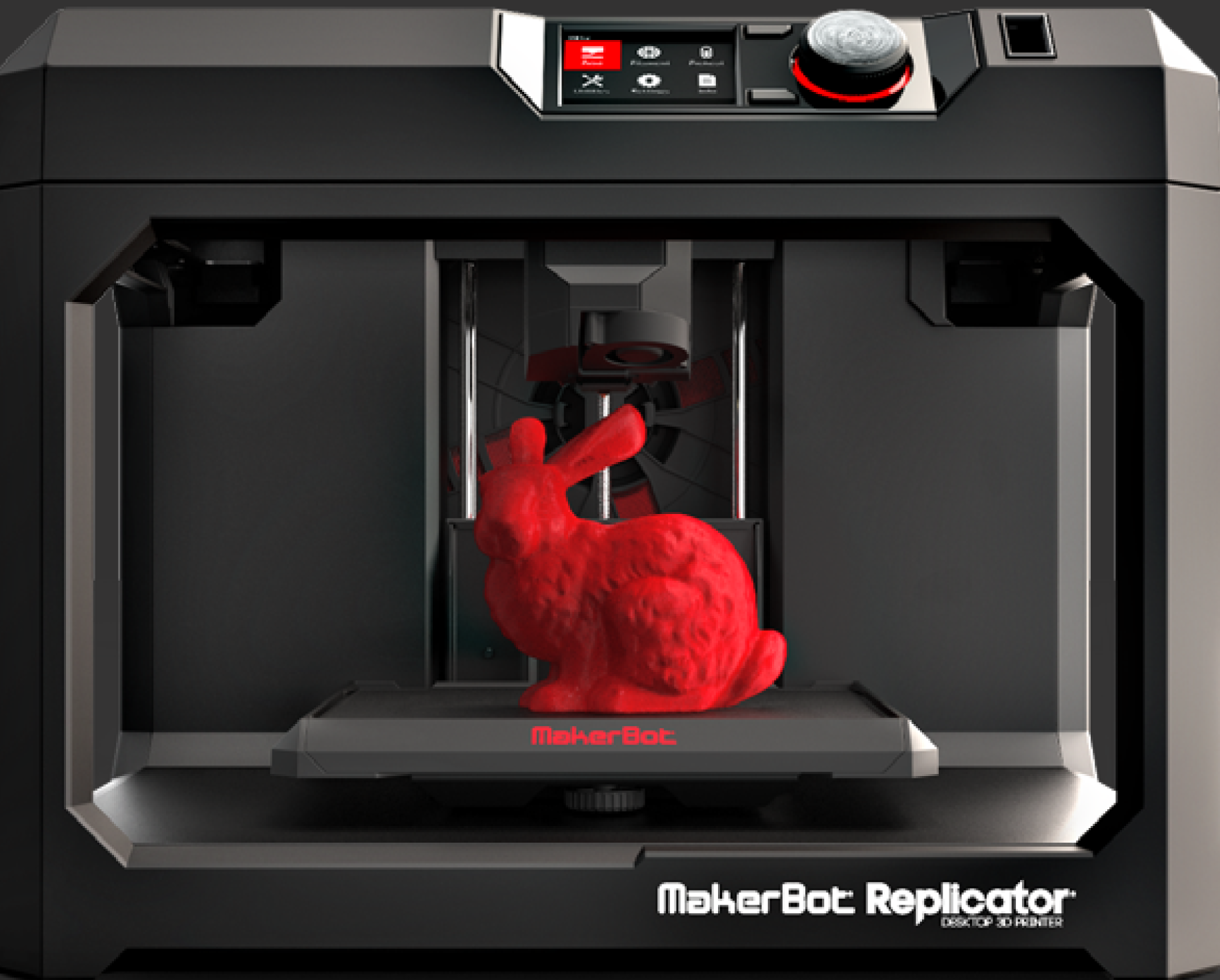

MAKERBOT® REPLICATOR® DESKTOP 3D PRINTER

THE EASIEST AND MOST VERSATILE WAY TO GET FROM 3D MODEL TO 3D PRINT

- Fifth generation technology defines the new standard for ease of use, quality, and reliability

- Powered by the new, user-friendly MakerBot Replicator 3D Printing Platform

- App and cloud enabled

- USB and Ethernet connectivity ensures a seamless production workflow

- New MakerBot Replicator Smart Extruder, Motion controllers, and gantry design

- On-board camera and diagnostics, and assisted build plate leveling

LARGE BUILD VOLUME ACCELERATES RAPID PROTOTYPING AND MODEL MAKING

- Makes true-to-life objects quickly and easily

- Enables you to manufacture on demand

- Optimized for MakerBot PLA Filament

100-MICRON LAYER RESOLUTION

- Each 100-micron layer is about as thin as a sheet of paper

- Create professional-quality, high resolution prototypes and complex models

- Get smooth-to-the-touch surfaces that don't need sanding, finishing, or postproduction

- Create realistic prototypes and models for demonstrations and presentations

- Choose settings that range from fast draft to finer resolution

MAKERBOT® REPLICATOR MINI® COMPACT 3D PRINTER

EASY AND AFFORDABLE 3D PRINTING

- Trust in a 3D printer that's durable, reliable, and easy to use

- Print, manage, and share your 3D creations simply and seamlessly, with free MakerBot software for your PC or Mac

- Experiment with a wide range of forms, colors, and textures

- Transform a small desk in your home or classroom into an exciting creative center

- Remix and customize your creations to create unique gifts for family and friends

ENTERTAINING, EDUCATIONAL, AND USEFUL

- Reconnect with your imagination and creative power

- Energize and inspire children's creativity, while preparing them for the jobs of the future

- Choose from hundreds of thousands of free, predesigned, and ready-to-print educational, entertaining, and useful 3D models on MakerBot Thingiverse®

- Shop for original, educational, fun, and collectible 3D models at the MakerBot Digital Store

- Spur social creativity at parties, events, and brainstorming sessions

KEY FEATURES

- MakerBot Replicator Smart Extruder that's easy to swap or replace and detects filament absence, automatically pausing your print

- Monitor your 3D prints via the onboard camera(also great for sharing your print to social networks)

- Send print files via USB cable

- Use the free MakerBot Desktop software to discover, manage, and share your 3D prints

MAKERBOT® FILAMENT

- Consistent diameter ensures smooth printing

- Helps produce higher-quality prints, fewer filament problems, and less downtime

- Trusted by leading companies and institutions the world over

- Safe for the classroom, office, or home, this filament is non-toxic and easy-to-print with minimal warping or curling.

Newsletter Signup

Sign up to our free newsletters and get the latest news from us delivered to your inbox.

Request a Quote

CAMWorks Modules

Program Smarter, Machine Faster

CAMWorks anticipates important technical trends.

We continuously enhance our products to meet the requirements of the machine tool industry

CAMWorks Modules

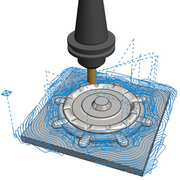

CAMWorks® with Machining Intelligence is the most advanced CAM programming software available for getting products to market faster, more efficiently and within budget. CAMWorks is a next generation best-of-class CNC programming solution that enables its users to program smarter and machine faster.

Program Smarter

Seamless integration within the design environment

CAMWorks offers true associative machining automatically accommodating changes to the part model, which eliminates time consuming CAM system rework due to design updates.

Being integrated into the design environment, CAMWorks allows a user to:

- Maintain associativity between the design model and the toolpaths ensuring that the latest changes in the design reflect in the toolpath

- Eliminate time-consuming file transfers using standard file formats such as IGES and STEP

- Use a single file for storing CAD and CAM data drastically reducing file management

- Work with the same familiar user-interface ensuring a short learning curve

- Use the CAMWorks machining tree and commands at the click of a button and generate toolpaths without leaving the design environment

CAMWorks provides users with the ability to work with multiple platforms including its own integrated CAD/CAM platform

Knowledge-based machining allows you to capture and reuse your programmers’ and machinists’ best programming practices using the Technology Database, TechDB™ reducing programming time by as much as 80%.

What differentiates CAMWorks from other software is the ability to store machining strategies feature-by-feature, both multi-surface features and prismatic features, and then reuse these strategies to reduce machining time significantly.

Feature-based machining: No profiles or chains

Feature-based machining reduces programming time by as much as 90% compared to traditional profiles, and chains based 3 axis CAM software because strategies for multi-surface features can be stored and reused automatically for multiple rough and finishing operations.

Our patented Automatic Feature Recognition (AFR) automatically recognizes over 20 types of prismatic features in native format or neutral file format solid models. This capability is ably complemented by Interactive Feature Recognition (IFR) for recognizing complex multi-surface features, as well as contains and avoids areas, quickly and easily.

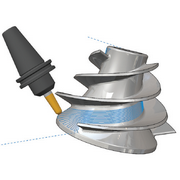

Machine Faster

We understand that only programming fast is not enough. Our users need to have access to the most advanced high speed machining strategies.

CAMWorks ensures that the air cuts are reduced to a minimum. In addition, users have access to optimized, out-of-the box, strategies for Mold core and cavity programming reduces programming time.

CAMWorks® Volumill™ creates ultra-high performance toolpaths by using the latest advanced technology to rough mill multi-surface parts faster than any other software available today. Reduce machining time by as much as 85% and increase tool life by as much as 500% even in the hardest materials.

CAMWorks Milling software for G-code programming CNC mill machines is available in a variety of configurations, so you can purchase exactly what you need now and add to your CAM system as your business grows:

- 2.5 axis, 3 axis, 4 and 5 axis Prepositioning

- 4 and 5 axis Simultaneous Milling

- 2 and 4 axis Turning

- Mill-Turning Machining

- Rotary Milling

- 2 and 4 axis Wire EDM

Photo Gallery

Career Opportunities

Kindly send your resume at This email address is being protected from spambots. You need JavaScript enabled to view it.

This email address is being protected from spambots. You need JavaScript enabled to view it.

Key Responsibilities:

- Source new sales opportunities through inbound lead follow-up and outbound calls and emails

- Route qualified opportunities to the sales team for further development and closure

- Research accounts, identify key players and generate interest

- Collaborate with Sales and Marketing teams to achieve quotas

Qualifications:

- Proficient in handling CRM

- Has excellent oral and written communication skills

- Hardworking and competent, with pleasing and good working ethics

- Very knowledgeable or enthusiastic about technology

- Willing to work full-time in Makati City

This email address is being protected from spambots. You need JavaScript enabled to view it.

Key Responsibilities:

- Provide technical support and assistance to clients

- Conduct SOLIDWORKS trainings to existing clients

- Make a Health Check on client’s usage and issues encountered

- Give recommendations or troubleshooting solutions on client's issues

Qualifications:

- Familiar with SOLIDWORKS or any 3D CAD software is an advantage

- Knowledgeable in manufacturing industry or related field

- Fast-learner, detail-oriented, highly motivated and with good work ethics

- Has excellent oral and written communication skills

- Willing to work full-time in Makati City

This email address is being protected from spambots. You need JavaScript enabled to view it.

Key Responsibilities:

- Support the Senior Accounting Officer by handling day-to-day administrative and financial tasks

- Ensure accurate financial records and assist in reporting and compliance

Qualifications:

- Prior experience in an accounting or finance role is an advantage

- High level of multi-tasking and time management capability

- Attention to detail and ability to identify financial discrepancies

- Integrity and professionalism

- Proficiency in Microsoft Office

- Willing to work full-time in Makati City

This email address is being protected from spambots. You need JavaScript enabled to view it.

Key Responsibilities:

- Transport company personnel, goods, or documents to designated locations safely and timely

- Maintain, clean, and report any issues of the company vehicle regularly

- Follow traffic laws and company driving policies

- Assist and communicate with passengers effectively and represent the company professionally

Qualifications:

- Has valid driver's license and clean driving record

- Has an ability to follow GPS or read maps

- Punctuality, reliability, and physically fit

- Willing to work flexible hours, including weekends or holidays if needed

- Trustworthy and able to handle confidential company materials responsibly

Kindly send your resume at This email address is being protected from spambots. You need JavaScript enabled to view it.

Blogs

- SOLIDWORKS Innovation Day 2026: Let's Amaze Together (Events & Webinars)

- Model Mania: Academe 4 (Events & Webinars)

- Recognizing our Women Elite Applications Engineers on International Women’s Day (Computrends News)

- CRE Partner Sales Kick Off & Marketing Summit (Events & Webinars)

- 3DEXPERIENCE® Works Innovation Day: Collaboration through Cloud (Events & Webinars)

- Metals and Engineering Week 2023 (Events & Webinars)

- Overcome these Business Challenges with DraftSight (SOLIDWORKS)

- AP South SOLIDWORKS VAR Sales Kickoff 2023 (Events & Webinars)

- Fast Facts: DraftSight 2D Design (SOLIDWORKS)

- Top 5 3DEXPERIENCE World 2023 Highlights (Events & Webinars)