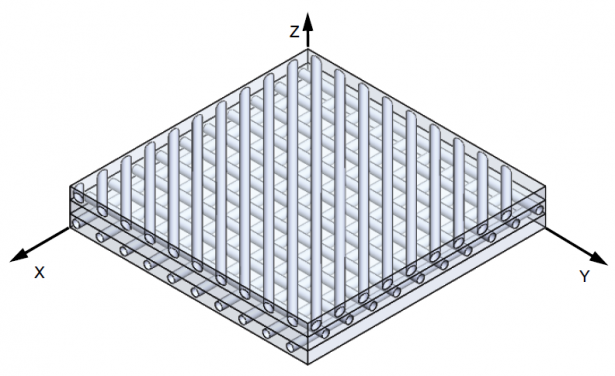

Normally, the components can be physically identified and exhibit an interface between one another. The basic difference of composite materials with, for example, metals is that they have an ‘Anisotropic’ behavior which means that the habits of the composite material or formed laminate are directional depended. Metals on the other hand, have in general an ‘Isotropic’ behavior which means that their habits are in all directions the same.

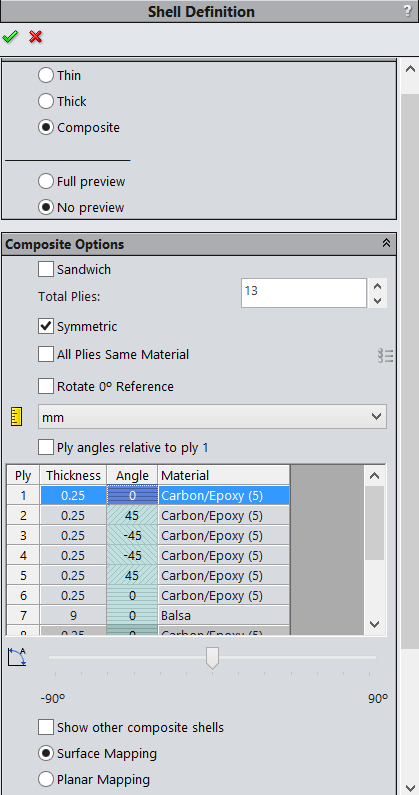

SOLIDWORKS Simulation helps analyze symmetrical and unsymmetrical composite layups, as well as composite sandwiches. Each layer can be defined by a unique set of material properties and orientation, giving the designer maximum control to find the optimum layup and material for maximum product performance.

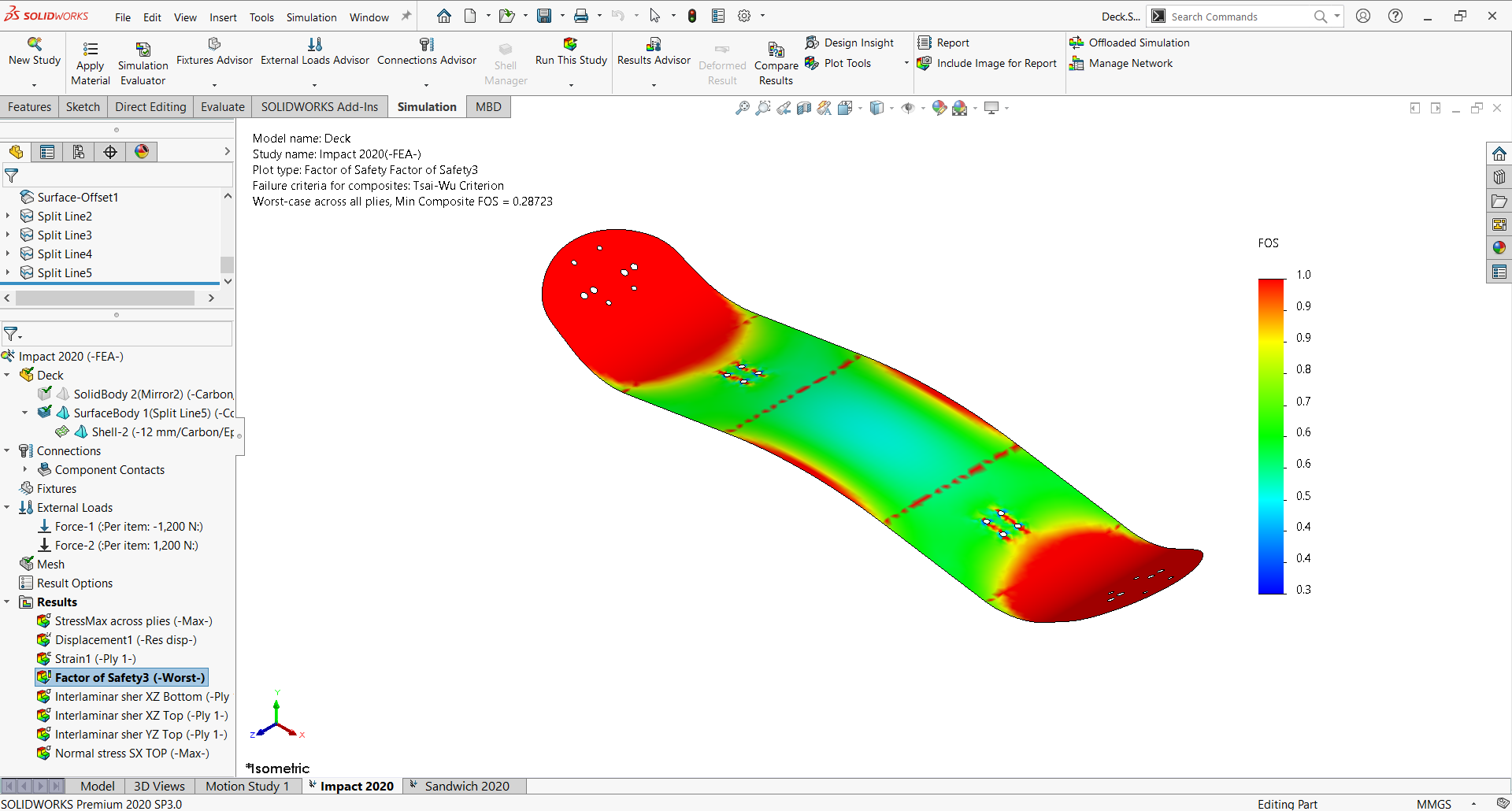

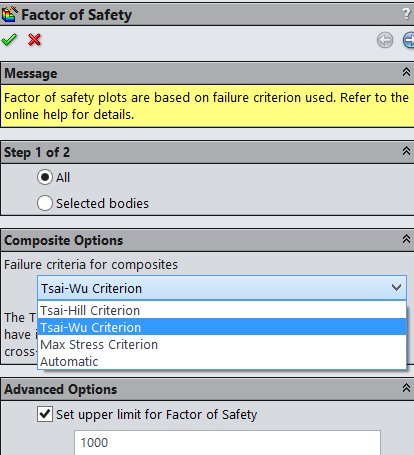

The failure criterion for composite materials is very different than for metals. Composite materials do not yield; rather, the fibers delaminate and fracture. SOLIDWORKS Simulation reports the FoS against failure according to the Tsai-Wu and Tsai-Hill failure indexes.

SOLIDWORKS Simulation uses FEA methods to discretize composite components into shell elements and uses stress analysis to determine the response of parts and assemblies due to the effect of forces, pressures, contact between components etc.

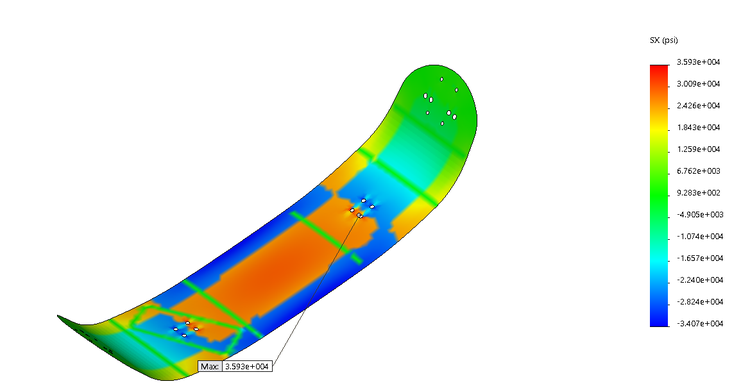

Stress plot displays the maximum stress values of the specified component (envelope plot) across all plies. The program includes the Top and Bottom faces while searching for the extreme value across all plies.

There are 3 Failure Criteria for composites you can choose from. Tsai-Hill Criteria is best applied to composite materials that have equal strengths in tension and compression and cross-fiber stress is primarily in tension. Tsai-Wu Criteria is best applied to composite materials that have inequal strengths in tension and compression and the cross fiber stress is primarily in tension. Max Stress Criteria is best applied to composite where the cross-fiber stress is primarily in compression.

SOLIDWORKS Simulation is the best tool to understand complex component responses with analysis of composite parts. You can optimize material selection and the number and orientation of the composite ply layup to ensure quality, performance, and factor of safety (FoS).